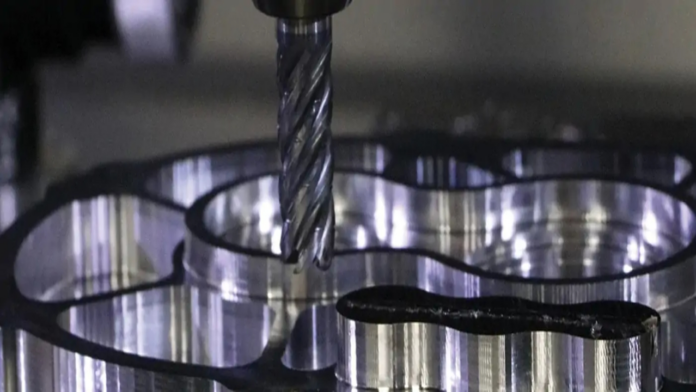

In the world of machining, CNC machines play a vital role in the production of high-precision parts. These machines have revolutionized the manufacturing industry by improving accuracy, speed, and repeatability in the production of complex parts. However, without the use of high-quality materials, these machines would not be able to perform to their full potential. Stainless steel is one such material that is widely used in CNC machine projects.

In this blog, we will explore the role of stainless steel in CNC machine projects and why it is crucial to use high-quality materials for precision engineering.

Durability and Corrosion Resistance:

Stainless steel is known for its excellent corrosion resistance, making it an ideal material for use in CNC machine projects. It is highly durable and can withstand exposure to harsh environmental conditions, making it perfect for use in the production of machine parts that are likely to be exposed to corrosive substances. Moreover, the use of high-quality stainless steel ensures that the machine parts have a longer lifespan and require less maintenance.

Precision and Accuracy:

CNC machines are designed to operate at high speeds with exceptional accuracy and repeatability. The use of stainless steel in CNC machine projects helps to maintain this level of accuracy by providing the necessary stability and rigidity required by the machine parts. This is because stainless steel has a high modulus of elasticity, which means it can withstand significant loads and resist deformation. It also has a low coefficient of thermal expansion, which means it remains stable even at high temperatures, and this stability is crucial for maintaining precision in CNC machines.

Cost-Effective:

While stainless steel may be more expensive than other materials like aluminum or mild steel, it is still a cost-effective option for CNC machine projects. This is because of the material’s durability and corrosion resistance, which translates to lower maintenance costs, longer machine lifespans, and fewer part replacements. Additionally, the use of stainless steel in precision engineering ensures that there are fewer errors in the production of parts, reducing the production time and overall cost of the project.

Versatility:

Stainless steel is a versatile material that can be customized to suit various machining applications. It can be easily formed, cut, and welded, making it ideal for complex designs. Additionally, it is available in different grades that can be chosen based on the specific requirements of the CNC machine project, such as the amount of corrosion resistance, strength, and cost.

Environmental Benefits:

The use of high-quality stainless steel in CNC machine projects is not only beneficial economically and technically, but it is also environmentally friendly. Since stainless steel is durable, it has a lower environmental impact as it reduces the frequency of replacements, reducing waste materials. Moreover, stainless steel is recyclable, and the scrap generated during the production process can be recycled and used to manufacture new machine parts.

Conclusion:

In conclusion, the use of high-quality stainless steel in CNC machine projects is crucial for precision engineering. The properties of stainless steel, such as its durability, corrosion resistance, precision and accuracy, cost-effectiveness, versatility, and environmental benefits, make it an ideal choice for CNC machine parts manufacture. Therefore, it is essential to use only the highest quality materials in CNC machine projects to ensure that they perform to their full potential and provide maximum benefits to the manufacturing industry. For more info contact us.