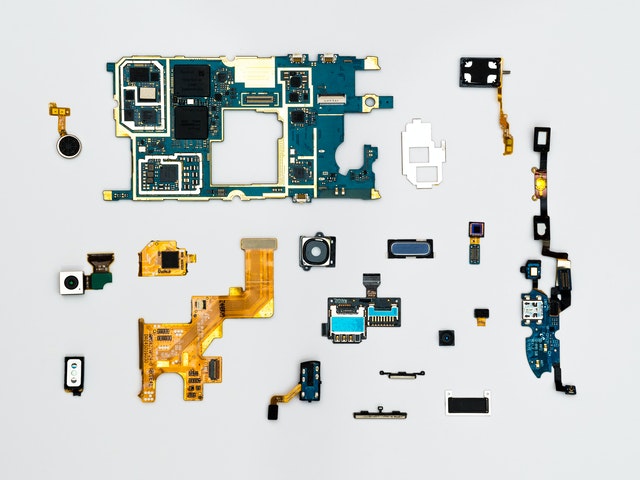

Rapid prototyping is the type of technology that has well evolved from traditional technology of having raw material to a cutting process to the finished product. Technology has now made it easier to cut materials without using tools manually. Manufacturers develop prototypes by designing models of parts of the product to be assembled using 3D printing technology. This article has covered all the basics of CNC prototyping machines you need to know. Before understanding how prototyping works, you need to know what custom machining is.

What Is Custom Machining?

Machinists refer to this as a low volume production to particular specifications requiring precision, punctuality, and a range of affordable costs. Low production costs are what a reputable CNC prototype manufacturing company is well accustomed to. Also, the process is essential in making material designs with great accuracy and attention to detail. Not forgetting the flexibility of working with a wide range of materials, including metals and plastics.

What Are the Benefits of Custom Machining?

The following are the advantages of custom machining for its users:

- Uses low volume production on projects that have specific orders and require accuracy and attention to detail

- In most instances, a project may need a specific part for its production, but it may not be available. This is where a custom machine comes in and can be used in place of the parts missing

- It is also very advantageous to projects where accuracy, repeatability, and precision are of the essence custom. As the name suggests, this is a highly recommended method of production.

Importance of Prototyping

The most significant advantage of prototype machines is their high accuracy and precision, making them necessary in industrial manufacturing. It can remove and detect flaws that lower the possibilities of producing low-quality products out to the market during manufacturing. It also makes it easy for machinists to identify a problem that occurs, and it is being able to be rectified as production is still ongoing.

Why CNC Prototyping Machines Are the Best for Manufacturing

Generally, CNC is the best option for manufacturing in large-scale industrial manufacturing, but CNC is way more beneficial than just the standard production setting.

Here are some advantages of prototyping machines.

1. Repeatability

Understand that CNC machines usually are software controlled programs. This means that as long as you have fed the input data and program to the machine, you can run as many designs as possible.

2. They Have Less Likelihood of Committing Errors

Human is to error, and prototyping machines reduces the chances of mistakes by minimizing those that are likely to occur during manufacturing. Also, CNC prototyping machines don’t experience frequent interruptions. Hence, production is a continuous non-interrupted process.

3. Prototyping Machines Are Time Friendly

The CNC machining is essential in that it can take a significant order of design inputs and take little time to make the product, all without reducing its quality.

Conclusion

The above information will help you understand various aspect of prototyping machines. Now, you understand how CNC concerns prototyping, how the two correlate, and their necessity in manufacturing.